Wafer Grinding, Lapping and Polishing Consumables and Repair Parts

Glemco is a Turnkey Solution for Semiconductor Wafer Manufacturers

We carry stock of high use ion implantation consumables, manage in site inventory, customize kitting or labeling.

We have a broad, high quality product line of ion implantation consumables for the entire beamline, full of innovative solutions.

We perform refurbishments and repairs of assemblies critical to ion implantation.

We provide experienced technical support and the best customer service experience.

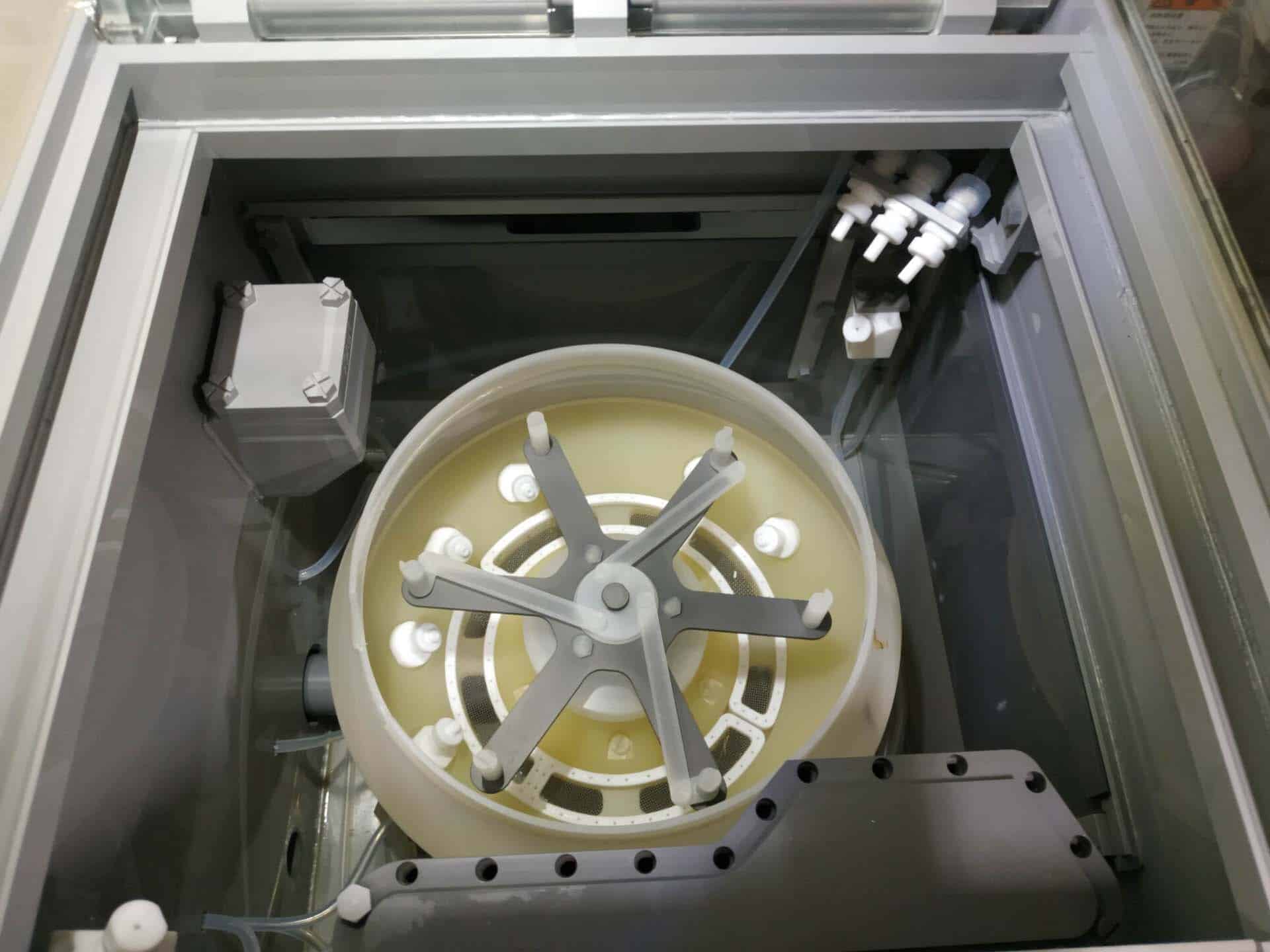

Consumables and machine maintenance and support for DNS® / AS-2000

DNS® / DAINIPPON® AS-2000 is a wafer grinding, lapping & polishing equipment that ensures reliable and consistent results over a range of sample sizes. The system features an efficient, cost-effective workflow that is designed to achieve accurate surface finishing and lapping with the greatest precision. The unit uses a vacuum-sealed chamber to conduct mechanical grinding and polishing. This chamber is equipped with a programmable robot arm that can move to the sample material, responsible for the lapping process. The sample is then propelled by a combination of centrifugal forces and atmospheric pressure. This enables the polishing and lapping to be executed simultaneously and quickly, creating a uniform surface finish. DNS® AS2000 includes several features that optimize the cost effectiveness of the wafer grinding and polishing process. It features a high-precision motor drive control machine that offers adjustable operation speeds, which allows for increased accuracy and efficiency. Additionally, it offers a highly automated process that is designed to minimize manual intervention.

DNS® / AS-2000 Components

DAINIPPON® AS 2000 also offers a variety of components that are suitable for a range of applications. These components include a compact grinding and polishing head, sample holders, precision grinding plate, and drag-type diamond disc. All these components are specially designed for reliability and efficiency. To ensure accuracy, the tool utilizes built-in optical sensors to accurately measure the sample material. This ensures the precise size and shape of the samples is accurately maintained. The asset’s control interface allows for easy operation and use. It features a user-friendly, intuitive graphical user interface that can be seamlessly integrated with the designer’s application software. This interface enables the user to easily control and monitor each step of the wafer grinding, lapping, and polishing process. DNS® AS-2000 provides a flexible range of grinding and polishing parameters that offers a cost-efficient solution for wafer grinding and polishing.

Since 1984

We are proud to support our local communities with jobs that offer good working environment, excellent pay and benefits, growth opportunities and stability. Proud to be an American Manufacturer and a Woman Owned Business.

Contact Us Today